If you need to weld two workpieces (for example, round pipes, steel bars, shock absorber rods, etc.) as evenly as possible, then you can use a homemade device.

In this review, the author shows how to make a conductor for welding workpieces in one plane.

In the home workshop or garage, such a homemade product definitely will not be superfluous. Moreover, to make it quite simple.

To make a conductor, you will need two pieces of a corner, a pair of studs (or you can use bolts without caps), two bushings from a half-inch pipe, two nuts.

The main stages of work

First of all, it is necessary to cut off two pieces of a corner 65 * 65 mm 30 cm long. We make a marking and cut out the "windows".

In the blanks, it is necessary to cut two viewing "windows" through which welding will be performed. In the upper workpiece, it is additionally necessary to cut two more “windows” into which the nuts will be welded.

Cut parts from the corners do not need to be thrown away. The author welds them to the conductor as supporting elements.

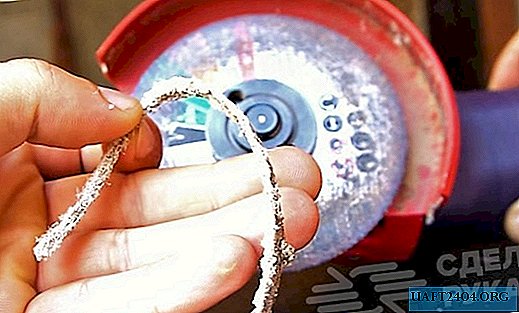

Next, we cut off two studs with a diameter of 15 mm, put bushings from a half-inch pipe on them, and scald. Drill holes with a diameter of 10 mm in these bushings.

At the last stage, “fingers” must be inserted into the drilled holes in the bushings to make the winders. After that, we weld all the construction details together.

For details on how to make a conductor for welding workpieces in one plane, see the video on the site.