In many homes, in the garage or in the workshop, rubbish is often collected in the form of scraps of a polypropylene pipe and damaged fittings (for example, they remained after repair).

If you don’t know where to attach them, take note of the recycling idea.

In this review, the author shows how to make a pulley out of unnecessary scraps of PP pipes. In principle, you can use another plastic: plastic caps, PET bottles, plastic cans, etc.

First of all, it will be necessary to cut the pieces of PP pipe into small pieces (so that they melt faster). And then we put them in a metal container.

The main stages of work

We put a container with plastic "garbage" on a gas stove (it is better to make a fire on the street) and wait until the plastic melts and turns into a homogeneous liquid mass.

After that, remove the container with plastic from the fire and leave it for a while, so that the mass inside it cools down.

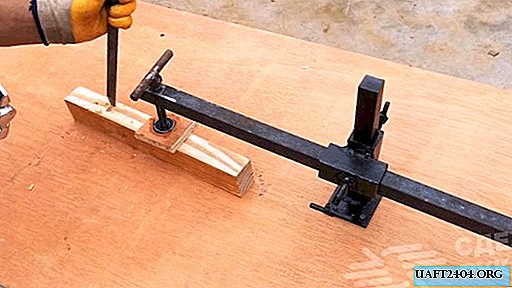

Next, we take the workpiece from the mold and process it on a lathe.

We recommend you to read: how to make a desktop mini lathe based on an electric drill with your own hands.

At the last stage, it remains only to groove a groove under the belt. A hole in the center of a homemade pulley is drilled directly to a specific diameter of the motor shaft.

For details on how to make a pulley from unnecessary scraps of PP pipes, see the video on the site.