Most often, carbon tool steel is used to make a kerambit knife. However, in this case, the author decided to make a kerambit knife from a disk harrow - as a rule, it is made of structural spring steel grade 65G.

The dimensions of the knife can be any - at your discretion. And the first thing to do is to use a grinder to cut out a L-shaped plate from the harrow.

The author heats the workpiece in the furnace, and then aligns it on the anvil, since the harrow has a concave shape.

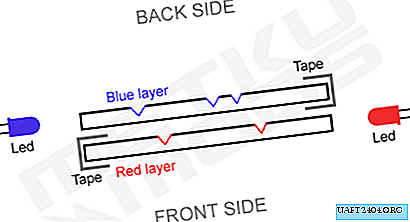

After that, you need to glue a paper template on the plate and cut the blank for the knife, after drilling holes for marking.

The main stages of work

After you cut the workpiece, you need to process its inner edges with a drill. Then we grind the outer sides of the workpiece on the grinder.

At the next stage, the author forms descents on the blade and sharpenes the blade. After that, the blade will need to be hardened. The procedure is standard: we heat the blade red, and then immerse it in a container with used oil.

After hardening, the author makes a vacation of steel, and then the final sharpening of the blade follows. At the last stage, it remains only to make the grip plates, stick them to the handle and process.

In detail about how to make a stylish kerambit knife with your own hands from a piece of a disk harrow, you can watch the video on our website.