Often, for grinding and polishing metal (mainly to remove paintwork - when performing bodywork) the so-called soft abrasive discs are used.

Actually, there are no complaints about them, except for one - they are not cheap. However, you can make homemade soft abrasive discs, which are almost as good as the factory ones, but will cost less.

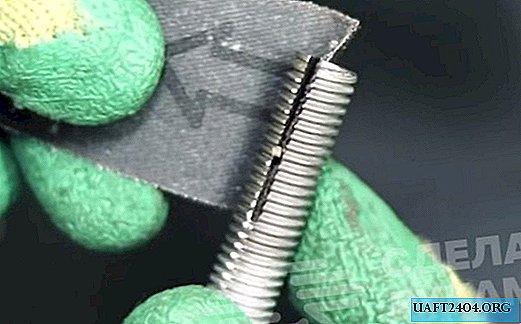

And for this you need a regular abrasive mesh. We cut it with scissors into pieces of the right size. For the grinder, we cut the net in half, for the dremel, we cut the smaller squares.

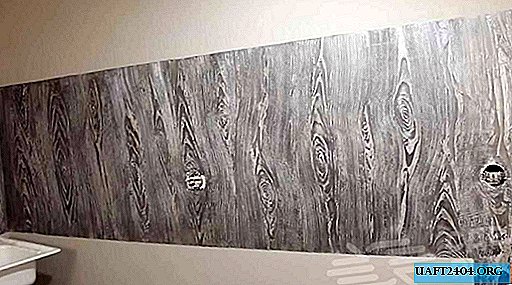

It should be noted that a home-made soft abrasive disc is quite suitable for removing rust on the metal surface.

The main stages of work

Further, after slicing suitable-sized pieces of abrasive mesh, you can begin to manufacture the softest disk.

There is nothing complicated here - you just need to make a hole in the center of the cut pieces of the net so that you can put them on the shaft.

When working with such grinding discs, it is extremely important to use safety glasses, as pieces from the abrasive mesh fly in different directions. Gloves, by the way, will also not be superfluous.

This grinding disc, although simple, but quite versatile. It can be used for "delicate" grinding of not only metal but also wooden workpieces.

For details on how to make soft abrasive discs for a little grinder and dremel, see this video. If you liked this idea, write about it in the comments.