For many novice craftsmen to buy a good drilling machine is an expensive pleasure. However, it can be assembled independently from different trash, which can be found in the workshop or garage.

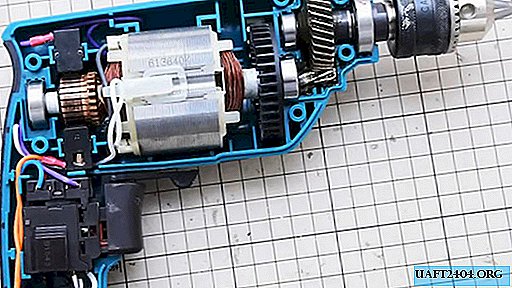

For example, in this case, the author uses as a basis a reducer from a grinder, as well as an engine from a washing machine with a power of 650 W. To produce this machine, metal pieces and some other details are still required.

First of all, it will be necessary to cut four pieces of a building corner 63 * 63 mm 120 mm long, as well as four pieces of a metal pipe with a diameter of 20 mm and also a length of 120 mm.

The main stages of work

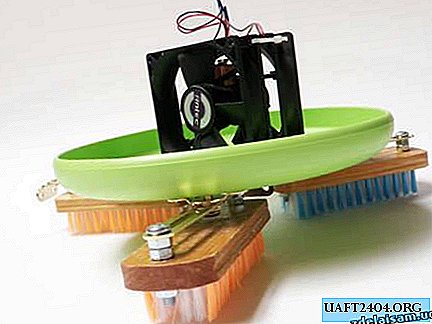

In each segment of the building corner, it will be necessary to drill two holes (in one of the shelves). Then, with the help of bolts, the corners are attached to the engine housing from the washer.

After that, previously cut sheet metal blanks are welded to the corners. On the edges of the resulting duct sections of the metal pipe are welded.

In the next step, from the two long sections of the corner and two steel plates with a thickness of about 10-12 mm, it is necessary to weld the base of the drilling machine. Dimensions - 400 * 210 mm. “Paws” are welded to the bottom of the strip.

Next, four racks (rails) 600 mm long are welded to the base of the drilling machine, on which a box with the engine from the washing machine will then be worn. For the manufacture of racks, the author uses a steel bar with a diameter of 15 mm.

At the last stage of work, the entire structure is assembled. For more information on how to make a drilling machine from a angle grinder and an engine from a washer, we recommend that you look in the video on the website.