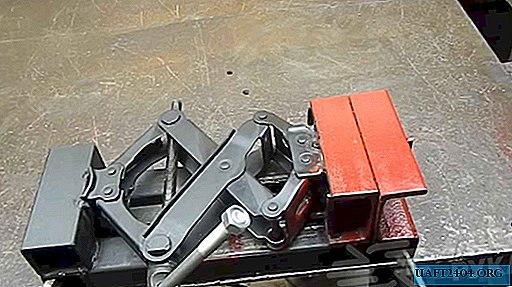

Even an old unnecessary car jack, which has not been used for its intended purpose for a long time, can be adapted for some interesting and useful project.

For example, from it you can make simple and convenient bench vice, which is quite suitable for work in the home workshop.

Of course, it will be much easier for someone to buy ready-made vices. However, if there is a bit of free time available, and you like to make different homemade products and appliances, then why not make a vise with your own hands?

In addition to the jack itself, for the manufacture of a vice you will need: a piece of a channel and suitable sections of a profile pipe of various sizes (40 * 40 mm, 30 * 30 mm and 25 * 25 mm). And the first thing you need to cut the blanks for homemade.

The main stages of work

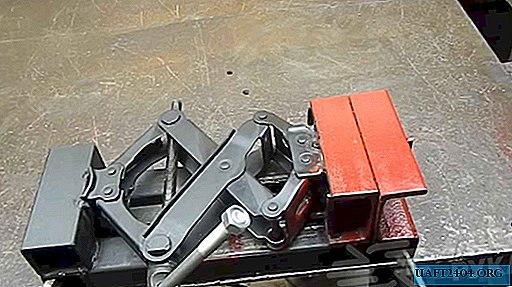

Of the four blanks cut from a profile of 40 * 40 mm, the master welds a rectangular frame, which will serve as the basis for a bench vise. Before welding, be sure to maintain a right angle.

At the next stage, two pieces 140 mm long will need to be cut from the channel - these will be clamping jaws.

The "sole" of the car jack must be cut off with a grinder so that it fits tightly inside one of the jaws of a bench vise (movable). They are connected by welding.

A profile pipe 25 * 25 mm is installed inside the frame, on which the master puts on a piece of pipe 30 * 30 mm. A movable sponge from the channel must be welded to it. On the jaws of the vice themselves, it will be necessary to make notches.

At the last stage, it remains only to weld to the base the emphasis for the jack from the profile. Then you can begin to assemble the entire structure.

Details on how to make a bench vise for a workshop from a car jack can be found in the video on the website.