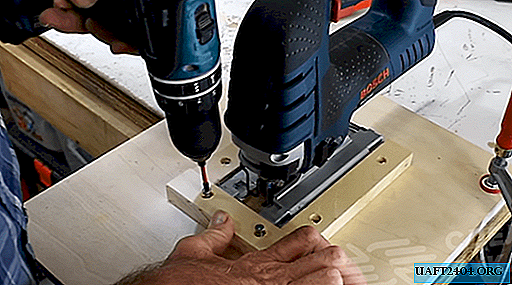

It is not so easy to remove bearings from the shaft, and even more so - to press them out of a blind landing at home. However, for this you can make a homemade universal puller for bearings. Of the basic materials, two pieces of pipe, an anchor bolt, and ordinary bolts with nuts will be needed.

To make this puller, you need to find two pieces of pipe of different diameters (the point here is that one pipe freely fits into the other). From a pipe of larger diameter, cut a piece about 10 cm long, and from a smaller one - 3-4 cm.

We make markings on a piece of sheet metal with a thickness of 4-5 mm and cut two circles to the diameter of the cut pipes. We process workpieces on an emery or belt grinder so that their edges are even.

Bearing puller manufacturing process

The resulting "plugs" must be welded to the ends of the workpieces. We clean the welds using a flap grinding wheel or another method available to you. In the center of the lid we drill holes.

Using a small grinder (a large one will be inconvenient) we cut out a small "window" in a pipe 10 cm long, and in a smaller segment we make a cut. After that, around the perimeter of the workpiece, it is necessary to drill holes for the bolts.

At the last stage of work, it remains only to drill three holes in the lid of a long pipe and cut the thread. After that, we proceed to the assembly of the device itself. For details on how to make a universal bearing puller with your own hands, see the video on the website.