Using a simple home-made machine for the production of fuel briquettes, it is possible to produce “bricks” from paper and cardboard. Thus, the waste paper accumulated in the corner can be used for heating a private house, garage or cottage.

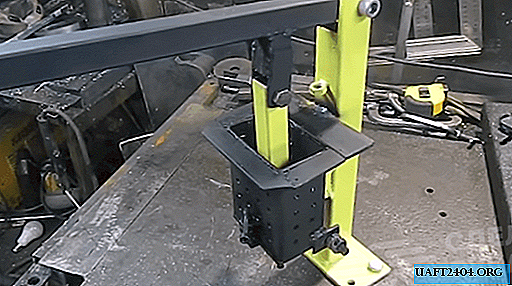

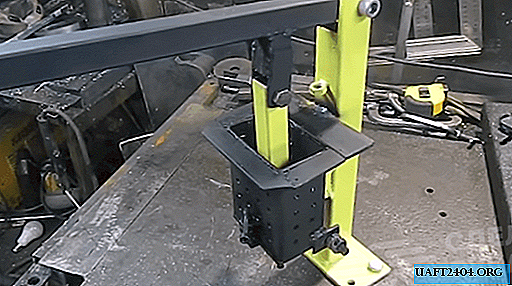

To make a matrix, to make a press, a profile pipe of rectangular cross section 100x60 mm will be required. The wall thickness is preferably at least 3 mm. The length of the profile should be 12 cm. If necessary, more can be done.

After cutting the workpiece, we mark with a ruler or vernier caliper, and drill through holes with a drill with a diameter of 6-8 mm. Then we cut off a small piece of a building corner about ten centimeters long. It will be used for pressing.

The main stages of work

The profile matrix, as well as other structural elements of a homemade paper briquette machine, need to be securely fixed. To do this, you need to make something like a frame with a bed. As the main materials, a square professional pipe 40x40 mm with a steel plate 5-6 mm thick and 15x7 cm in size is suitable.

At the next stage of work, we weld the matrix with a connecting element from a profile of 40x25 mm. After that, we weld the stand itself from the 40x40 mm trade pipe to the resulting part. Then from the sleeve from the reactive thrust, it will still be necessary to make a hinge system.

The result is a simple device for pressing cardboard and paper. The step-by-step process of manufacturing a homemade machine for the production of fuel briquettes, see the video on the site.