Is your kitchen knife rusted and dull? Are you going to throw it away for scrap? Do not rush to do this! Even from the oldest and most ordinary-looking kitchen knife, you can make a beautiful and original thing - for example, a Japanese knife.

The first step is to remove the pads on the handle of the kitchen knife. To do this, take a drill and drill rivets. Then, using a marker or a white corrector, draw new contours that will correspond to the classic shape of a Japanese knife. All excess should be cut off with a grinder.

On the tail of the knife we make shallow cuts. After that, we process the metal surface, as well as update and sharpen the cutting edge of the blade on the grinder. You can also use a conventional emery machine for this. Subsequent grinding and polishing is done manually.

The process of burnishing a knife blade

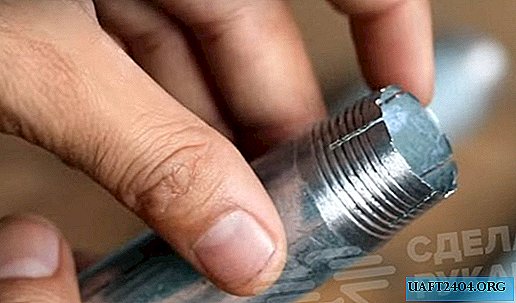

One of the ways to protect the knife from corrosion is the chemical etching method (metal burnishing). Dissolve approximately 100-150 grams of citric acid in 500 ml of water. After this, you must first degrease the surface of the blade, and then lower it into a solution of citric acid.

Approximately 20-30 minutes after the start of the chemical etching reaction, the blade must be removed, the black plaque formed, and then again immersed in the solution.

To obtain a better result, it is advisable to repeat this procedure with a knife several times. Then we proceed to the manufacture of the bolster and the handle.

At the last stage of work, we collect all the elements together. For more information on how to make a Japanese knife from an old kitchen knife, see the video on the website.