To make one home-made clamp, you will need a piece of a profile pipe 30x30 mm long about 40-50 cm (if necessary, you can use a longer length), two sections of the profile 40x40 mm, as well as two pieces of steel angle with dimensions 40x40 mm. To connect the parts you will need bolts with nuts.

The main stages of work

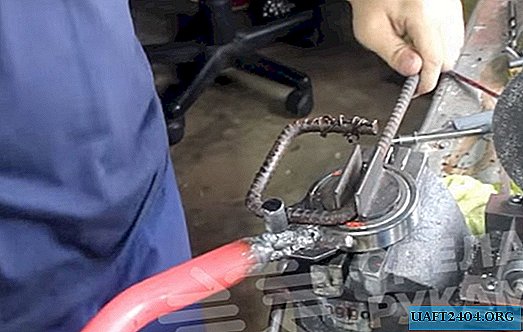

First of all, it is necessary to weld the steel corners to the sections of the profile pipe 40x40 mm - they will be worn on the guide profile 30x30 mm. Then, in the frame of the G-shaped clamp, we drill four holes on the drilling machine, and cut it into two parts, so that the upper clamping jaw and the screw with the nickle are separate from each other.

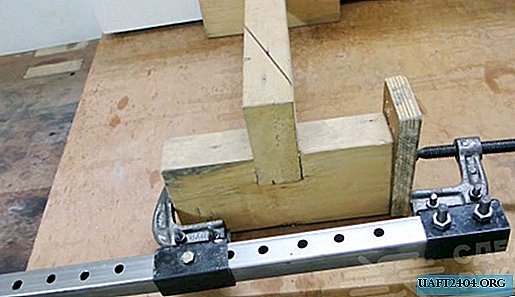

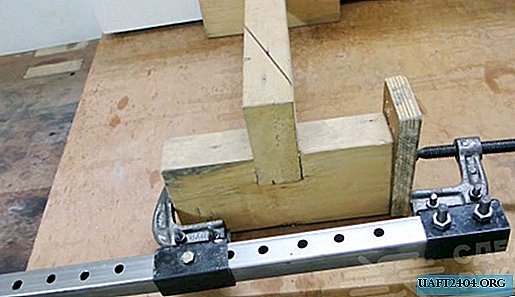

We mark and drill two holes in the corners, and it will also be necessary to make holes in the guide profile pipe with a step of 5 cm. Now that all the main parts are ready, you can proceed with the assembly of the home-made structure.

Using bolts and nuts, we fasten the upper part of the clamp to one of the corners, and to the other - the lower half of the frame with a screw and a clamping nickle. Then we fix both parts on the guide profile at the required distance from each other.

The result is a powerful universal clamp, which is useful when working with workpieces made of wood and metal. See the step-by-step assembly process in the video on the site.