Home-made clamps made of a rectangular profile are perfect for fixing various small parts. As clamping jaws, you can use pieces of steel angle with side dimensions of 10x10 mm. Also required are studs with nuts and two large washers.

The main stages of work

From the profile of 20x40 mm, we cut four identical pieces 18.5 mm long. We cut the edges on one side at an angle and drill through holes in the narrow part of the profile. Then you need to drill one more hole in each workpiece at a distance of about 8-10 cm from the edge.

We connect the two halves of the clamp with a wing nut with a bolt, we fix a steel plate on top of the profile pipes at the edges. We fix one side of the plate with the help of a segment of a stud with two nuts, and the other - scald.

On the opposite side we weld sponges from a steel corner 10x10 mm. Moreover, on the surface of the clamping jaws, it is necessary to make notches with the help of a grinder so that the fixed part does not slip and does not rotate during processing.

Finishing touch

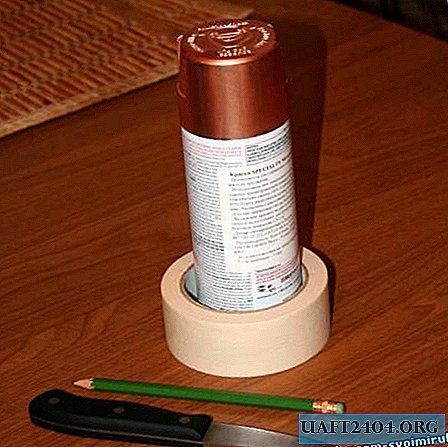

We clean the surface of the profile and the place of welding, after which the clamps can be painted with spray paint for a more aesthetic appearance. We cut off the hats of the bolts - we weld the washers instead. The result is two hand clamps that are useful when performing various locksmithing or welding work with small parts. See the step-by-step manufacturing process in the video on the website.