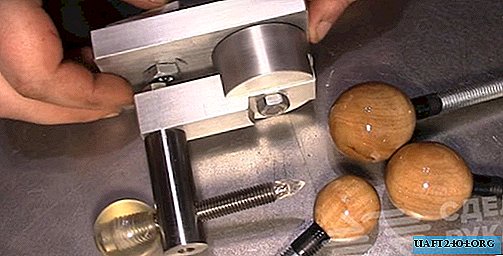

The quality of processing of wooden and metal workpieces (parts, products, etc.) during the execution of locksmith and carpentry work is significantly improved if you use various auxiliary devices - for example, metal clamps.

Almost every workshop has clamps and clamps of various designs and sizes. However, as they say, a good tool does not happen much. The functionality of many factory models is often limited by the small size of the frame.

Therefore, it’s nice to have at hand a universal home-made clamp, which is easy to do yourself from available materials.

Manufacturing process

We cut two identical “barrels” from a steel pipe of a suitable diameter, in the center of which then one hole will need to be drilled. Also for this home-made clamp you will need four metal plates with a width of 2 cm and a thickness of 6 mm.

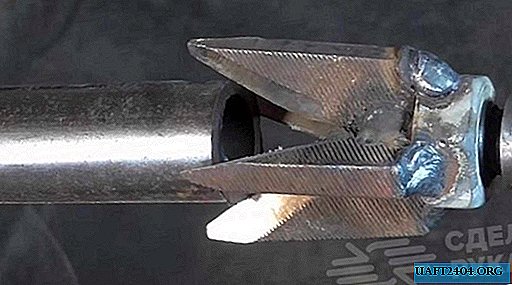

First, we weld two plates to the walls of each "barrel", and then we weld together their opposite ends. Two nuts with a bolt must be welded to the edge of one of the resulting workpieces (to the end part), and a wide metal washer of suitable sizes to the side of the other.

A piece of steel round timber should also be welded to the bolt stud. After this, the welds must be cleaned with a grinder, and the working elements of a home-made clamp can be painted to protect against corrosion. After that, it remains only to put everything together, and the tool is completely ready for work.