Such a wooden dining table is convenient and simple in design, and at the same time, despite the use of budget materials, it looks quite aesthetically pleasing - it will be nice to hold various celebrations behind it or just gather with the whole family on the weekend.

Manufacturing process

To make curly legs, you will need to buy a furniture panel 18 mm thick (but it is better to buy a shield thicker - 40 mm). The scraps that remain after cutting the legs will also be used in the manufacturing process of the table.

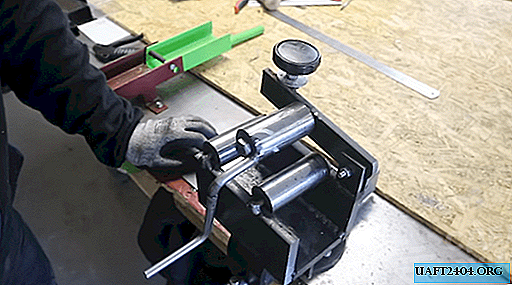

If you will cut the legs from a furniture board 18 mm thick, then you will additionally need to strengthen them - for this you need to use a wooden rail, in which you need to use a hand milling cutter to select a groove about 17.5-17.6 mm wide and 2 cm deep.

The lower tsar with a width of 12 cm and a thickness of 30 mm can be made of a board that is used to decorate the bath (sold in building hypermarkets). Also, the curly legs of the table will be interconnected with the help of two bars in which you need to choose two eyes - a wooden lintel is very tightly fitted in them.

Dining table assembly

On the lower part of the curly legs it is necessary to "fit" wooden slats with a groove, screwing them with two screws (only not from the edge, but closer to the center). Next, the lower side is screwed to the legs, the end of which is preferably lubricated with carpentry glue for greater reliability. Then the upper czars with eyes are installed.

When the underframe is completely ready, it remains only to securely fix the countertop. See the detailed process of assembling the table in the video on our website.