With the help of this homemade product you can quickly and without any hassle cut even clear circles from sheet metal. The minimum diameter of a circle that can be cut with a grinder on this fixture is 24 cm, and the maximum is 700 mm (but it can be cut up to two meters).

Manufacturing process

For this homemade product you will need the following materials: 16 mm stud, 16 mm elongated nut, bearing and steel housing for it, two sections of the profile pipe (one with sides 25x25 mm, the other 20x20 mm), a strip segment 40 mm wide, and neodymium magnet, which can be ordered on the Internet.

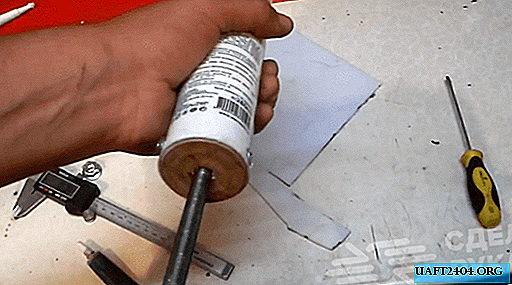

First of all, we install the bearing in the landing "socket" of the housing, and from the back of the workpiece we weld an elongated nut. After that, it is necessary to press the housing with the bearing and the elongated nut onto the seat of the neodymium magnet.

We screw a segment of the stud into an elongated nut, and then screw a segment of the profile pipe to it with nuts welded to it from both sides.

The final stage of work

Three plates must be cut from the steel strip, from which then it will be necessary to make a mount for the grinder, welding them together and drilling holes of a suitable diameter. Then, on the upper part of the resulting casing, you need to weld a handle-lever with a movable end.

The resulting structure, together with the grinder, needs to be fixed on a steel sheet (using a neodymium magnet), and then, setting the required radius, you can begin to cut the circle. This device is very convenient to use, and everyone can make such a stand.