When you need to cut a workpiece from metal or wood at an angle of 45 or 90 degrees, then for this it is better to use a rack for the grinder.

This device can be made without problems with your own hands, using improvised materials: plywood and shaped pipes.

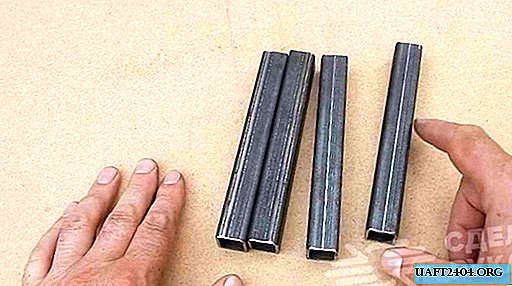

The first step is to cut four pieces of profile 20 * 20 mm with a wall thickness of 2 mm.

We make markings and drill holes in each workpiece: on one side we retreat from the edge of 1 cm, on the other - 3 cm.

After that, from pieces of a metal strip, cut to size, you need to make a mount for the grinder.

The main stages of work

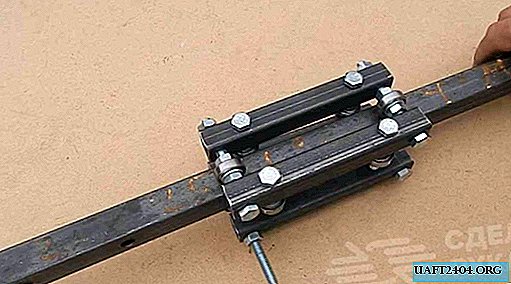

The next step will require pieces of the profile pipe with previously drilled holes, bearings, bolts with nuts and washers, as well as a piece of the stud.

From all these details, the author collects a guide system. A profile pipe is inserted into the resulting fixture. Then adjustment is made - it is necessary to tighten the nuts to get rid of backlash.

Next, you will need two more pieces of the profile pipe and two pieces of the building corner. We weld the parts together. In the corners we drill fixing holes.

In the profile pipes, it will be necessary to drill one hole in which we insert the elongated nuts.

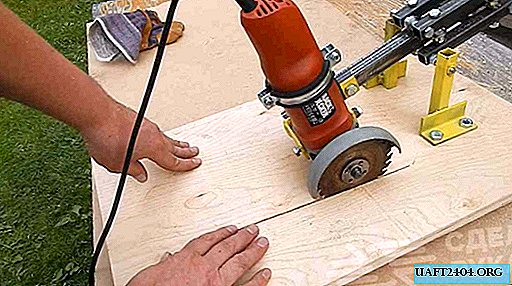

We make the basis of plywood. We fasten the parts from the corner and the profile to the base, and fix the fixture made of segments of the profile pipe 20 * 20 mm.

We install the mount on the grinder and attach the profile pipe to it, which is then inserted into the guide system.

At the last stage, we fasten to the base a stop bar for blanks made of a corner. The bar itself can be set at an angle of 90 and 45 degrees.

For details on how to make a budget rack for angle grinders, see the video.