The regular handles of an angle grinder (small or large - it does not really matter) are fixed tightly. But sometimes it’s convenient for the handle to be bent at a certain angle — for example, when grinding or cutting parts in hard-to-reach places.

To do this, you need to slightly modify the regular handle of the grinder, making it rotary. This will expand the functionality of the angle grinder.

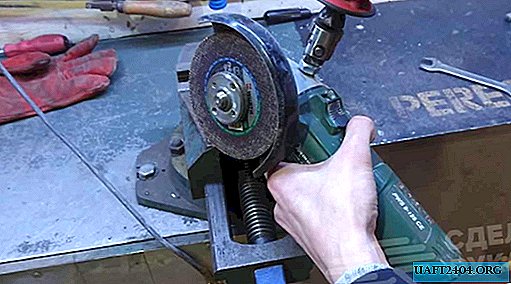

First of all, the master selects a nut for the diameter of the pin of the angle grinder handle and welds it to the main part - a roller and a bolt with a clamp. Previously, in the metal case in which the roller "sits", you need to cut out the grooves on the sides.

The main stages of work

Then you need another small bolt, in which you need to cut off the edges of the cap on both sides. Next, this bolt must be welded to the roller. Then it remains only to clean the welds with a petal circle.

The modified handle is screwed into the angle grinder body, and you can work. However, the design is not the most reliable, so care must be taken when working.

Turning the handle during operation, if you only hold on to it, may result in personal injury. Especially on angle grinders with discs with a diameter of more than 125 mm.

For details on how to modify the regular handle of a small grinder (angle grinder), see the video on the site.